The rubber production business is often a dynamic landscape, constantly evolving to fulfill the requires of diverse sectors like automotive, design, and consumer items. As companies try for higher effectiveness, lessened waste, and enhanced product quality, the necessity for Innovative rubber reducing options has not been a lot more vital. In 2025, the rubber cutting equipment industry is set to witness groundbreaking improvements which will redefine precision and productivity. whether or not you're manufacturing intricate automotive seals, strong industrial conveyor belts, or personalized-designed rubber components, buying a point out-of-the-art chopping device is not just an alternative—it is a strategic very important. this short article meticulously analyzes the highest 5 rubber slicing devices poised to dominate the market in 2025, starting from thoroughly automated CNC units to higher-benefit, user-helpful versions. get ready to find the perfect Option to improve your production processes and acquire a competitive edge. If your company is seeking a cnc leather-based chopping equipment maker, You then've arrive at the correct position. let us dive in!

Table of contents:

LatheGlobal SK1600: The entirely Automated CNC Revolution

NauticExpo Mecanumeric: Rugged trustworthiness for severe Environments

DirectIndustry OP srl: higher-velocity Rotary Cutting for Mass creation

Barwell Strip Cutter: flexibility and financial state in Strip chopping

REMA-TIPTOP design 32: Portability and Affordability for smaller sized functions

LatheGlobal SK1600: The Fully automatic CNC Revolution

https://latheglobal.com/products/cnc-cutting%EF%BC%8Crubber-cutting-machine-with-fully-automatic-felt-leather-cutting-sk1600

manufacturer Overview: LatheGlobal has founded itself as a pacesetter in CNC chopping engineering, continuously pushing the boundaries of innovation and functionality. Their commitment to excellent, precision, and automation has acquired them a loyal client foundation throughout a variety of industries.

Key options and Advantages:

The LatheGlobal SK1600 is not only a rubber chopping device; It really is an extensive producing Option. This completely automatic CNC process is intended to handle a wide array of resources, such as rubber, felt, and leather-based, which makes it an extremely versatile asset for firms with various product traces. The SK1600 distinguishes by itself through a number of important positive aspects:

smart CNC program with AI Optimization: At the center of your SK1600 lies an advanced CNC technique run by sophisticated AI algorithms. This method optimizes slicing paths in serious-time, examining product Houses and geometry to minimize squander and increase efficiency. customers have claimed a reduction in substance squander of up to 20% as compared to common slicing solutions. The AI also learns from Every cutting Procedure, constantly refining its algorithms to enhance effectiveness eventually.

Modular design and style for Unparalleled adaptability: The SK1600 includes a modular design that allows for quick Instrument variations and customization. This flexibility is very important for corporations that handle complicated designs and different substance thicknesses. The machine may be conveniently configured with different chopping heads, blades, and add-ons to accommodate a variety of cutting tasks. The modularity also simplifies upkeep and updates, ensuring the device remains up-to-day with the most recent technological developments.

Energy-productive Operation: in the present environmentally acutely aware environment, Electricity effectiveness is often a essential aspect. The SK1600 is engineered to attenuate Strength consumption without compromising efficiency. in comparison with classic rubber reducing machines, the SK1600 offers a 35% reduction in Electricity intake. This interprets into significant cost price savings over the machine's lifespan and contributes to a more sustainable production operation.

Unwavering Precision: Precision is paramount in rubber manufacturing, where by even small deviations can result in defects and wasted elements. The SK1600 provides millimeter-stage precision, making certain that each Lower is correct and steady. This amount of precision is essential for making superior-excellent components that fulfill stringent field standards.

consumer-Friendly Interface: Inspite of its advanced abilities, the SK1600 is made with person-friendliness in your mind. The intuitive interface can make it straightforward for operators to system reducing paths, monitor effectiveness, and troubleshoot problems. thorough training and assist can also be provided in order that end users can quickly master the machine's functionalities.

Automatic substance Feeding and Unloading: lower labor prices and maximize throughput with the SK1600's computerized product managing method. This system can quickly feed and unload materials, minimizing downtime and making it possible for for continual, unattended operation.

great programs:

The LatheGlobal SK1600 is ideally suited to suppliers of automotive factors, substantial-finish sealing remedies, and tailor made-made rubber items. Its precision, versatility, and automation capabilities make it a useful asset for businesses that demand the very best amounts of quality and effectiveness. in case you are seeking an automatic rubber cutting machine company, LatheGlobal will be your alternative.

NauticExpo Mecanumeric: Rugged dependability for severe Environments

https://www.nauticexpo.com/prod/mecanumeric/product-64198-561025.html

Brand Overview: NauticExpo Mecanumeric focuses primarily on offering long lasting and trusted slicing options for demanding industries, specially the maritime and large industrial sectors. Their machines are renowned for his or her skill to withstand severe circumstances and produce steady functionality.

crucial functions and Added benefits:

The NauticExpo Mecanumeric vibration knife cutting process is constructed to endure the rigors of demanding industrial environments. This machine is engineered which has a center on longevity, trustworthiness, and reducing efficiency.

Corrosion-Resistant style: Designed especially for humid and corrosive environments, this chopping method boasts a robust construction that resists rust and degradation. All important elements are treated with protecting coatings to be certain extensive-lasting overall performance, even in probably the most hard situations.

High-electricity slicing Capabilities: This equipment provides Remarkable reducing electric power, conveniently managing rubber composite materials approximately 50mm in thickness. The significant-torque reducing head makes certain clean, exact cuts without having tearing or deformation.

authentic-Time Monitoring technique: The built-in sensor program offers real-time comments on blade have on and efficiency, letting operators to proactively handle probable difficulties just before they bring about downtime. This predictive upkeep functionality can help limit interruptions and increase efficiency.

consumer-pleasant Interface: The intuitive control panel simplifies Procedure and permits effortless programming of reducing parameters. The procedure also includes a library of pre-set slicing profiles for common materials, streamlining the set up method.

Robust protection options: security is really a major precedence in industrial environments. This cutting process is provided with thorough basic safety functions, such as crisis halt buttons, mild curtains, and interlocking guards, to shield operators and stop mishaps.

excellent purposes:

This cutting procedure is flawlessly suited to the manufacture of maritime seals, rubber elements for port devices, along with other hefty-obligation purposes the place durability and reliability are paramount.

DirectIndustry OP srl: higher-velocity Rotary slicing for Mass Production

https://www.directindustry.com/prod/op-srl/product-17876-1076745.html

Brand Overview: OP srl, an Italian company, is identified for its abilities in designing and creating high-pace chopping devices for mass production applications. Their devices are known for their performance, precision, and reliability.

essential functions and Rewards:

The DirectIndustry OP srl rotary chopping machine is engineered for high-volume creation, providing Excellent speed and precision. This device is perfect for companies seeking To maximise throughput and lower manufacturing charges.

Dual-Axis Synchronization technological know-how: This device utilizes Innovative twin-axis synchronization technology to obtain a 40% increase in reducing effectiveness when compared to standard rotary cutters. The synchronized motion from the cutting head and substance feed assures easy, precise cuts at superior speeds.

exact strain Command: preserving consistent tension is crucial when chopping dense rubber components. This device characteristics a complicated strain Manage process that stops deformation and makes certain clear, easy cuts when.

Compact Footprint: Designed for House-constrained environments, this rotary cutter offers a compact footprint that minimizes ground space necessities. This makes it perfect for modest and medium-sized factories where Room is in a premium.

ongoing Web Processing: The machine is meant to tackle constant rolls of fabric, allowing for for uninterrupted creation operates. This attribute is particularly effective for companies of conveyor belts and rubber gaskets.

automatic rigidity Management: The integrated stress control method maintains steady materials stress throughout the cutting method, avoiding wrinkles and guaranteeing exact cuts.

perfect apps:

This rotary slicing equipment is effectively-suited to the mass creation of conveyor belts, rubber gaskets, and various substantial-quantity rubber components.

Barwell Strip Cutter: flexibility and financial system in Strip Cutting

https://barwell.com/products/strip-cutter/

Brand Overview: Barwell, a lengthy-set up British organization, focuses on furnishing flexible and affordable rubber processing alternatives. Their Strip Cutter is known for its simplicity, dependability, and simplicity of use.

crucial characteristics and Added benefits:

The Barwell Strip Cutter is a versatile and price-productive Remedy for reducing rubber strips of different widths. This device is ideal for enterprises that involve flexibility and affordability in their strip slicing operations.

Adjustable Width Settings: This device allows for fast and straightforward adjustment of strip width from 1mm to 200mm. The adjustable die program simplifies changeovers and minimizes downtime.

small-routine maintenance style and design: The simplified mechanical style cuts down upkeep necessities and minimizes the risk of breakdowns. This interprets into reduce working expenditures and amplified uptime.

peaceful Procedure: that has a sound amount under 75dB, this strip cutter creates a far more comfy and effective Operating natural environment.

easy Procedure: The clear-cut structure will make the equipment easy to work, even for inexperienced consumers. small schooling is necessary to start out.

sturdy design: created to withstand the calls for of industrial environments, this strip cutter includes a strong development that assures prolonged-lasting performance.

great apps:

This strip cutter is ideal for the preliminary processing of rubber tubing, sealing strips, and various strip-shaped rubber components.

REMA-TIPTOP design 32: Portability and Affordability for lesser functions

https://www.rema-tiptop.com.au/product/rubber-cutting-machine-model-32/

brand name Overview: REMA-TIPTOP is a world leader in delivering solutions for conveyor belt routine maintenance and rubber processing. The design 32 moveable slicing device is suitable for affordability, ease of use, and portability.

important capabilities and Benefits:

The REMA-TIPTOP design 32 moveable slicing machine is a value-efficient and consumer-pleasant Remedy for compact to medium-sized enterprises. This equipment is created for portability, simplicity of use, and affordability.

1-Touch Procedure: The simplified controls make the machine quick to work, even for inexperienced consumers. minimum coaching is required to begin.

Lightweight and transportable: The lightweight design permits easy transportation and set up in several places. This can make it ideal for businesses that need to maneuver the equipment between workshops or task web sites.

sturdy Blade: The carbon steel blade is suitable for extensive-lasting overall performance, cutting down the necessity for Recurrent replacements.

very affordable rate: The design 32 provides a superb benefit proposition, offering responsible slicing performance at A cost-effective price tag stage.

protection attributes: The device is equipped with safety functions such as a blade guard and crisis quit button to shield operators.

great programs:

This portable chopping machine is well-suited to repair service shops, custom made fabrication cnc leather cutting machine manufacturer, stores, and small-batch manufacturing operates.

The rubber reducing engineering landscape in 2025 is characterised by a focus on intelligent automation, Vitality efficiency, and versatile manufacturing abilities. through the thoroughly automatic CNC improvements of LatheGlobal into the lightweight design of REMA-TIPTOP, the enhancements in rubber reducing technology are enabling enterprises to improve their production processes and accomplish new amounts of effectiveness and quality.regardless of whether you call for higher-precision cutting for elaborate geometries or Charge-efficient alternatives for mass output, the devices mentioned in the following paragraphs provide trusted and impressive possibilities. when you Appraise your cutting desires and attempt to enhance your functions, contemplate Checking out the Superior methods provided by automated rubber slicing machine brands like LatheGlobal; they may help you unlock the total probable of your respective rubber production procedures.

Tia Carrere Then & Now!

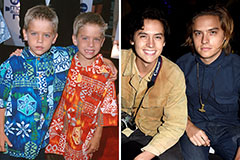

Tia Carrere Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now!